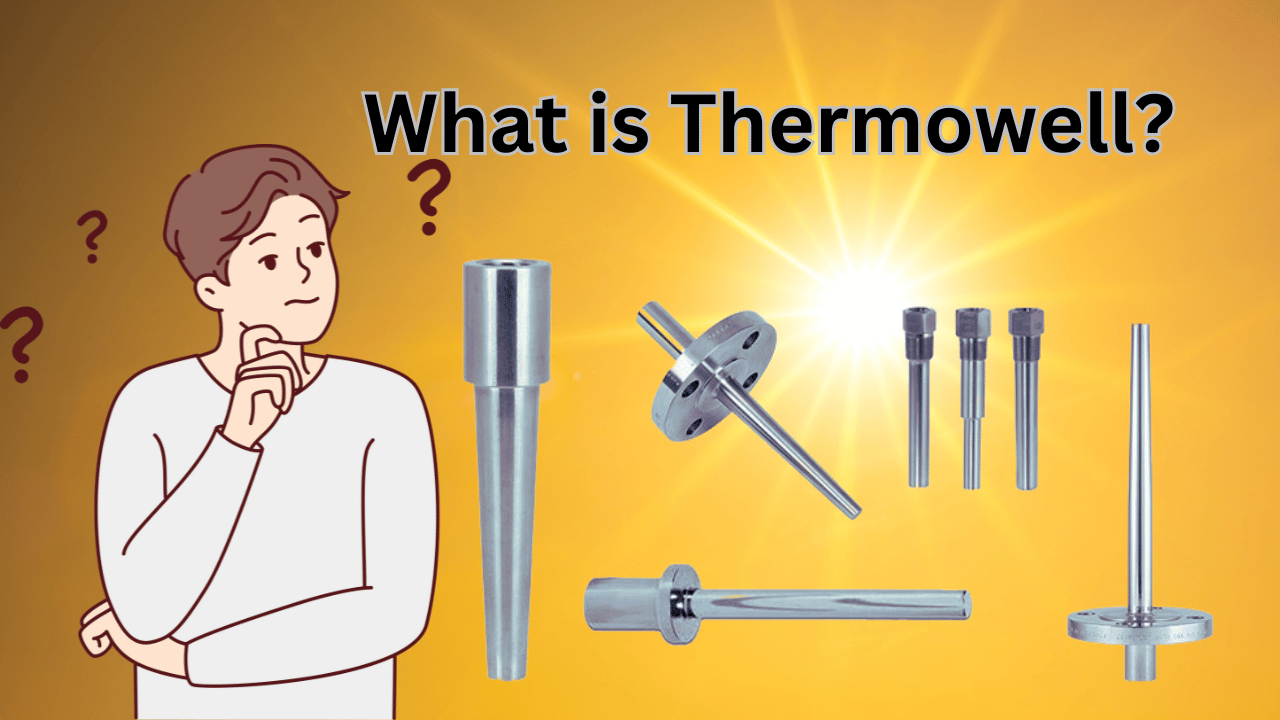

What is Thermowell?

In the realm of industrial processes, precise temperature measurement is paramount. Thermowells play a crucial role in this, providing protection to temperature sensors while ensuring accurate readings. Let’s delve into the intricacies of thermowells, exploring their types, materials, applications, and Standards.

.Types of Thermowells

Thermowells come in various types, each tailored to specific industrial needs. Threaded thermowells are commonly used for easy installation, while flanged thermowells offer stability in high-pressure environments. Weld-in thermowells provide a secure, permanent solution for extreme conditions.

Materials Used in Thermowells

The choice of material for thermowells is critical for their performance. Stainless steel is a popular option for its durability, while inconel and ceramic thermowells cater to specific applications where corrosion resistance or high-temperature resistance is paramount.

How Thermowells Work

The primary function of thermowells is to protect temperature sensors from harsh industrial conditions. By enclosing the sensor in a robust housing, thermowells shield it from corrosive substances, pressure, and physical damage, thus extending the sensor’s lifespan and facilitating easy replacement.

Applications of Thermowells

Thermowells find applications across diverse industries. In the oil and gas sector, they ensure accurate temperature readings in challenging environments. Chemical processing relies on thermowells for precision, while HVAC systems utilize them to maintain optimal operating conditions.

Choosing the Right Thermowell

Selecting the appropriate thermowell involves considering factors such as the type of process, fluid conditions, and temperature range. Matching the thermowell to the application is crucial for ensuring accurate and reliable temperature measurements.

Thermowell Installation Process

The proper installation of thermowells is crucial for their effectiveness and longevity.

Proper Positioning

The accurate positioning of thermowells ensures that temperature sensors receive precise readings. Factors such as flow dynamics and thermal conductivity must be considered during installation.

Factors Influencing Installation

Installation considerations include the type of thermowell, the medium being measured, and the specific requirements of the application. Adhering to recommended installation procedures is vital for optimal performance.

Common Challenges and Solutions

Corrosion and vibrations pose challenges to thermowell performance. Implementing corrosion-resistant materials and employing vibration-damping techniques are key solutions to mitigate these issues.

Importance of Thermowell Standards

Adherence to standards, such as those set by the American Society of Mechanical Engineers (ASME) PTC 19.3 and the International Organization for Standardization (ISO), ensures the reliability and consistency of thermowell design and performance.

Thermowell vs. Direct Temperature Measurement

Comparing the pros and cons of using thermowells versus direct temperature measurement methods helps in choosing the most suitable approach.

Advantages and Disadvantages

While thermowells offer protection and versatility, direct temperature measurement provides real-time data. Understanding the strengths and limitations of each method is crucial for making informed decisions.

When to Use Each Method

The choice between thermowells and direct measurement depends on factors such as the application’s requirements, environmental conditions, and the level of precision needed. Balancing these considerations ensures optimal temperature monitoring..

Thermowell Safety Considerations

Ensuring the safety of personnel and equipment is paramount in industrial settings. Proper installation, regular maintenance, and adherence to safety protocols contribute to a secure working environment.

Conclusion

In conclusion, thermowells are indispensable in industrial temperature sensing, offering protection, precision, and reliability. As technology continues to advance, the role of thermowells in optimizing industrial processes is set to become even more prominent.

Frequently Asked Questions (FAQs)

Q1. What is the primary purpose of a thermowell?

A1. The primary purpose of a thermowell is to protect temperature sensors in industrial processes, ensuring accurate and reliable temperature measurements.

Q2. Can a thermowells be reused after removal?

A2. In some cases, thermowells can be reused after proper inspection and assessment of their condition.

Q3. What materials are commonly used in the manufacturing of thermowells?

A3. Stainless steel, inconel, and ceramic are commonly used materials in the manufacturing of thermowells, each chosen for specific industrial applications.

Q4. Why is it essential to follow thermowell standards?

A4. Adherence to thermowell standards, such as those set by ASME PTC 19.3 and ISO, ensures the reliability and consistency of thermowell design and performance.

Q5. How can thermowell corrosion be mitigated?

A5. Thermowell corrosion can be mitigated by using corrosion-resistant materials and implementing proper maintenance practices.