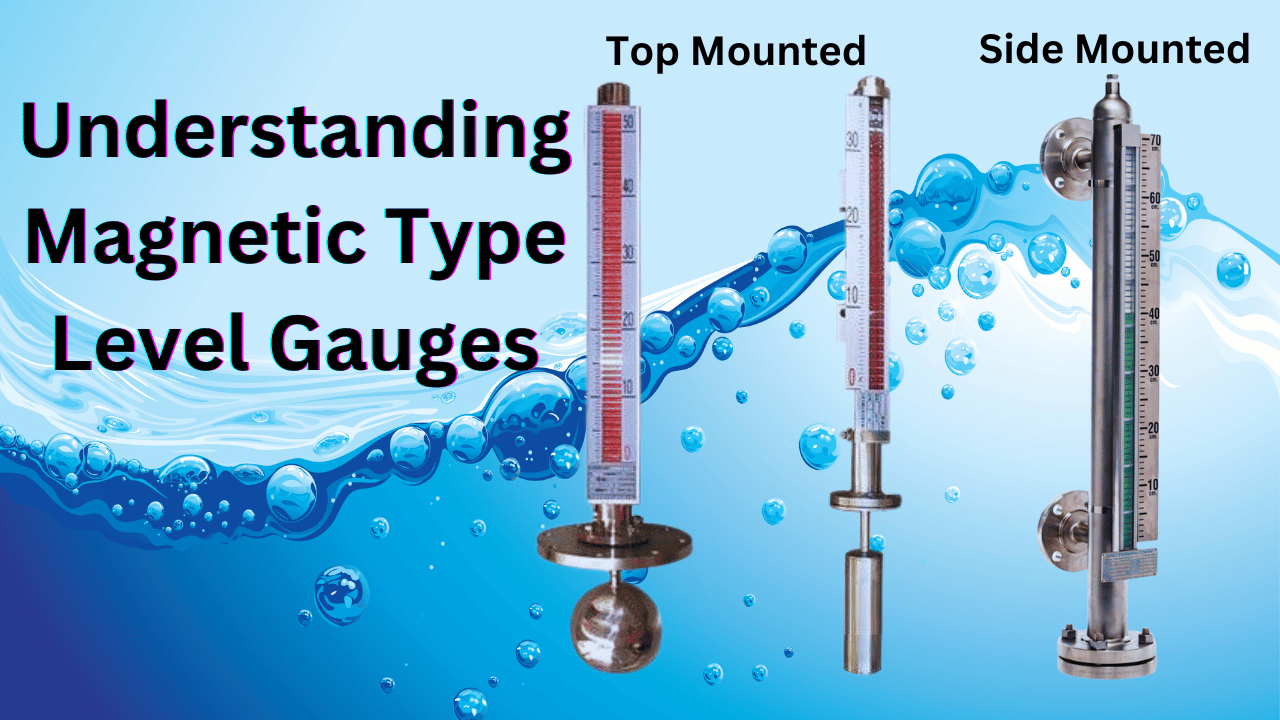

What is Magnetic Type Level Gauges?

In the world of industrial instrumentation, precision and reliability are paramount. Ensuring the accurate measurement of liquid levels in tanks and vessels is critical for various processes, from manufacturing to chemical processing. This is where magnetic type level gauges come into play. In this article, we will delve deep into the workings, advantages, and applications of magnetic type level gauges.

Introduction to Magnetic Type Level Gauges

Magnetic type level gauges are advanced instruments designed for the accurate measurement of liquid levels in various industrial settings. Unlike traditional float-type devices, these gauges rely on magnetic principles, making them highly reliable and suitable for a wide range of applications.

How Do Magnetic Type Level Gauges Work?

Understanding the Basic Principles

At its core, a magnetic type level gauge consists of a magnetic float inside a chamber attached to the side of a tank or vessel. The float moves up and down with the liquid level, and its position is detected by a series of magnetic sensors on the outside of the chamber.

Components of a Magnetic Level Gauge

A typical magnetic level gauge comprises several key components, including the float, chamber, magnetic coupling, and level indicator. These components work in harmony to provide precise level measurements.

Advantages of Magnetic Type Level Gauges

Magnetic type level gauges offer numerous advantages over traditional level measurement methods. These include:

- Accurate and reliable readings

- No contact with the process fluid

- Suitable for high-pressure and high-temperature applications

- Minimal maintenance requirements

- Compatibility with a wide range of fluids

Applications across Industries

Petrochemical Industry

In the petrochemical industry, accurate level measurement is crucial for safety and efficiency. Magnetic type level gauges are often used to monitor liquid levels in storage tanks, ensuring compliance with strict regulations.

Food and Beverage Industry

Hygiene and precision are paramount in the food and beverage industry. Magnetic level gauges are used to monitor levels of ingredients and products, ensuring quality control and adherence to recipes.

Pharmaceutical Industry

In pharmaceutical manufacturing, precise measurements are essential to produce consistent and high-quality products. Magnetic type level gauges play a critical role in maintaining accuracy.

Proper Installation

To ensure accurate readings, proper installation is crucial. Magnetic level gauges should be installed vertically, and care should be taken to eliminate any magnetic interference in the vicinity.

Other Level Measurement Technologies

While magnetic type level gauges offer many advantages, it’s important to consider alternative level measurement technologies such as ultrasonic and radar sensors for specific applications.

Safety Considerations

Safety is paramount in industrial environments. Magnetic type level gauges are inherently safe as they do not require direct contact with the process fluid, reducing the risk of leaks and accidents.

Cost-Effective Solutions

Despite their advanced technology, magnetic type level gauges often prove cost-effective in the long run due to their reliability and low maintenance requirements.

Customization Options

Magnetic level gauges can be customized to meet the specific requirements of different industries and applications, ensuring optimal performance.

Environmental Benefits

The minimal maintenance and reduced risk of leaks associated with magnetic type level gauges contribute to environmental sustainability.

Minimum ordering Information for Magnetic Level gauges

- Mounting Orientation – Top Mounted or Side Mounted

- C/C Distance (Center to Center distance) – Flange to flange center distance (applicable for side mounted only)

- Process Connection Size & Type – Connection Size, Type Screwed or Flanged and Pressure Rating

- MOC of Chamber and Float – Since it’s magnetic level gauge so Min. material would be Stainless steel (SS).

Conclusion

In conclusion, magnetic type level gauges are indispensable tools in industrial settings, providing accurate and reliable measurements for a wide range of applications. Their advantages, safety features, and environmental benefits make them a top choice for liquid level monitoring.

Frequently Asked Questions (FAQs)

Q1. Are magnetic type level gauges suitable for corrosive fluids?

A1. Yes, magnetic type level gauges can be constructed with materials that are resistant to corrosion, making them suitable for use with corrosive fluids.

Q2. Can magnetic level gauges be used in high-pressure applications?

A2. Absolutely, Magnetic type level gauges are designed to withstand high-pressure environments and provide accurate measurements under such conditions.

Q3. How often should magnetic level gauges be calibrated?

A3. Calibration frequency depends on the specific application and industry regulations. Typically, they should be calibrated at least annually or as recommended by the manufacturer.

Q4. Are magnetic level gauges compatible with non-metallic tanks?

A4. Yes, magnetic type level gauges can be adapted to work with non-metallic tanks by using special float materials.

Q5. Can magnetic level gauges be used for interface measurement in multiphase fluids?

A5. Yes, magnetic type level gauges can effectively measure interfaces between different liquids in multiphase fluids, providing valuable insights.