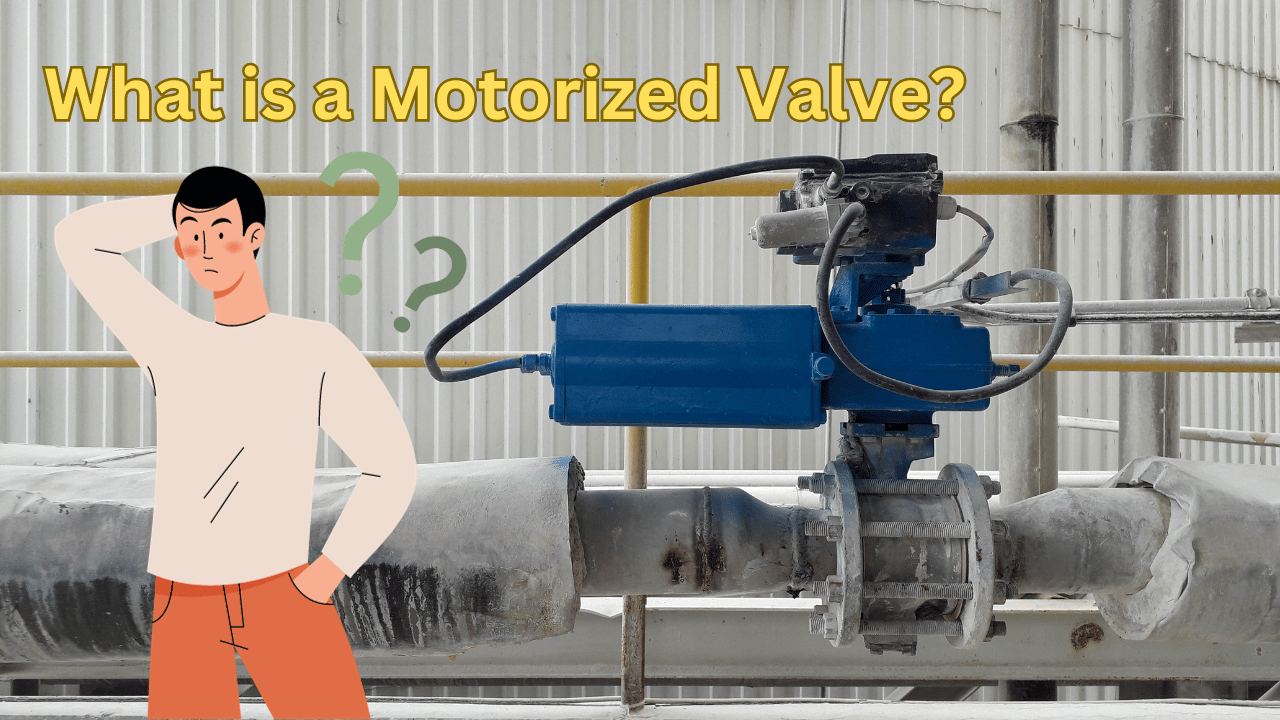

What is a Motorized Valve?

Motorized valves are a critical component in various industrial and residential applications, serving as automated gatekeepers for the flow of liquids or gases. These valves offer precision control, improving efficiency and ensuring the safety of operations in a wide range of industries. In this comprehensive article, we will delve into the world of motorized valves, exploring their types, functions, applications, advantages, and more.

Introduction

Motorized valves, as the name suggests, are valves that incorporate an electric or pneumatic actuator to control the flow of fluids or gases. These valves are used to start, stop, or regulate the flow within a system automatically. Unlike manual valves, motorized valves offer precise and often remote control, making them a crucial part of modern automation processes.

Types of Motorized Valves

Motorized valves come in various types, each designed to suit specific applications. The most common types include:

Ball Valves

Ball valves utilize a spherical disc to control the flow. When the ball is positioned in the path of the fluid or gas, it obstructs the flow, and when turned, it opens the pathway.

Butterfly Valves

Butterfly valves employ a flat, circular disc that rotates to control the flow. These valves are known for their quick operation and tight shut-off.

Globe Valves

Globe valves have a linear motion mechanism, making them suitable for applications where precise control is essential. They regulate flow by raising or lowering a plug into the path of the flow.

Gate Valves

Gate valves use a gate-like mechanism to control the flow. These valves offer low resistance when fully open but are not ideal for throttling applications.

How Do Motorized Valves Work?

Motorized valves function by using an actuator to move a closure element (e.g., a ball, disc, or plug) to control the flow of fluids or gases. The actuator can be electric, pneumatic, or hydraulic, and it receives signals from a control system to open or close the valve. This automated process ensures precise and timely control, making motorized valves highly efficient.

Applications of Motorized Valves

Motorized valves find applications in various industries, including:

- Oil and Gas

- Water Treatment

- HVAC Systems

- Chemical Processing

- Food and Beverage

- Pharmaceutical

- Power Generation

Advantages of Motorized Valves

The advantages of motorized valves include:

- Precise Control

- Remote Operation

- Reduced Maintenance

- Increased Efficiency

- Enhanced Safety

Disadvantages of Motorized Valves

Some disadvantages to consider:

- Higher Initial Cost

- Complex Installation

- Vulnerable to Electrical Failures

Importance of Motorized Valves in Industries

Motorized valves play a vital role in ensuring the efficient and safe operation of industrial processes. They reduce the risk of human error, enhance process control, and contribute to cost savings by optimizing fluid and gas flow.

Motorized Valves vs. Manual Valves

Comparing motorized valves to their manual counterparts, it’s clear that motorized valves offer superior precision and automation capabilities. Manual valves are simple but lack the efficiency and remote control options of their motorized counterparts.

Installation and Maintenance

Installation Process

Proper installation is crucial to the performance of motorized valves. It involves mounting the valve, actuator, and control systems, as well as ensuring electrical and pneumatic connections are secure.

Maintenance Guidelines

Regular maintenance includes inspecting for leaks, lubricating moving parts, and checking the electrical components. Preventive maintenance ensures the longevity and reliability of motorized valves.

Future Trends in Motorized Valves

The future of motorized valves lies in further automation, integration with smart systems, and enhanced energy efficiency. These trends will continue to drive the development of advanced motorized valve technologies.

Conclusion

Motorized valves are integral components in the industrial and residential sectors, enhancing control, efficiency, and safety. They offer a bridge to a more automated and efficient future, making them indispensable in various applications.

Frequently Asked Questions (FAQs)

Q1. What is the purpose of a motorized valve?

A1. Motorized valves are designed to control the flow of fluids or gases automatically, offering precise regulation and often remote operation.

Q2. Are motorized valves suitable for home use?

A2. Yes, motorized valves are used in homes, primarily in HVAC systems, to regulate heating and cooling.

Q3. How do motorized valves contribute to energy efficiency?

A3. Motorized valves can optimize the flow of fluids, reducing energy consumption by ensuring that systems only operate when necessary.

Q4. Can motorized valves be controlled remotely?

A4. Yes, many motorized valves can be controlled remotely, providing flexibility and convenience in various applications.

Q5. What industries benefit the most from motorized valves?

A5. Industries such as oil and gas, water treatment, and chemical processing benefit significantly from the precise control and automation provided by motorized valves.